HIT TYPE COMPLEX SORTER

- Invention Name: Impact Composite Sorter

- Field: Waste Sorting Technology, Recycling

- Core Technology: Centrifugal Impact, Wind Drying

- Objective: Removal of Foreign Materials and Moisture Drying

Sorter Overview

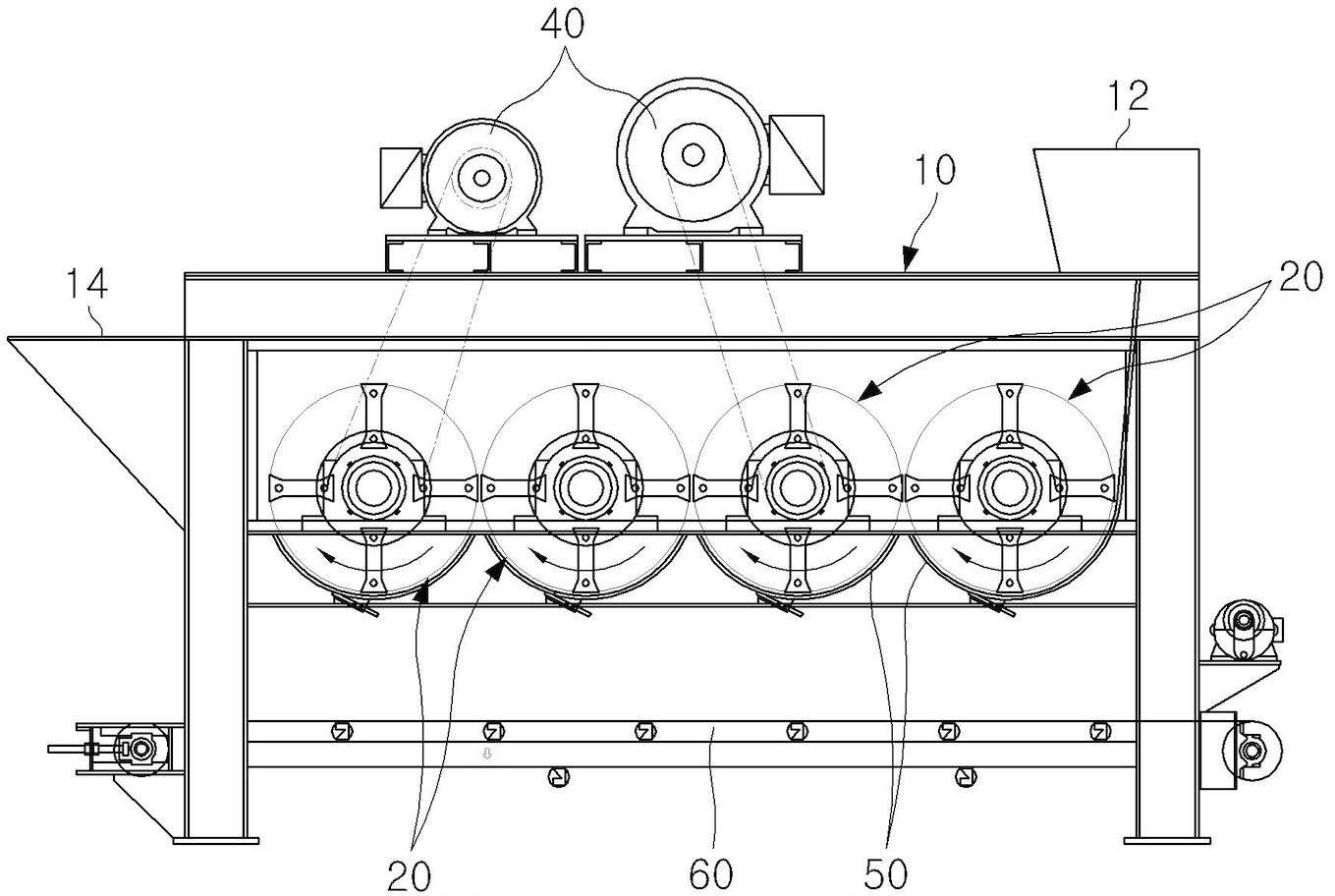

CI Ecotech's Impact Composite Sorter is an advanced sorting equipment that effectively removes foreign materials such as soil and moisture from waste such as waste synthetic resins through impact using centrifugal force and wind drying technology. Unlike conventional simple sorting methods, this sorter utilizes the centrifugal force generated in the sorting section to

perfectly filter out foreign materials and moisture adhering to waste, while simultaneously drying moisture through wind power generation. Precision rotating blades connected to the driving unit cooperate to perform efficient impact operations, and

selectively separate only foreign materials through a screen to produce high-quality recycled raw materials or industrial fuel.

The core of this sorter is the free rotation mechanism of the rotating blades and efficient foreign material separation through centrifugal force. In particular, the combination of the sorting section and driving section is an innovative solution that overcomes the limitations of existing technologies, simultaneously improving sorting efficiency and drying performance.

Core Technology and Sorter Configuration

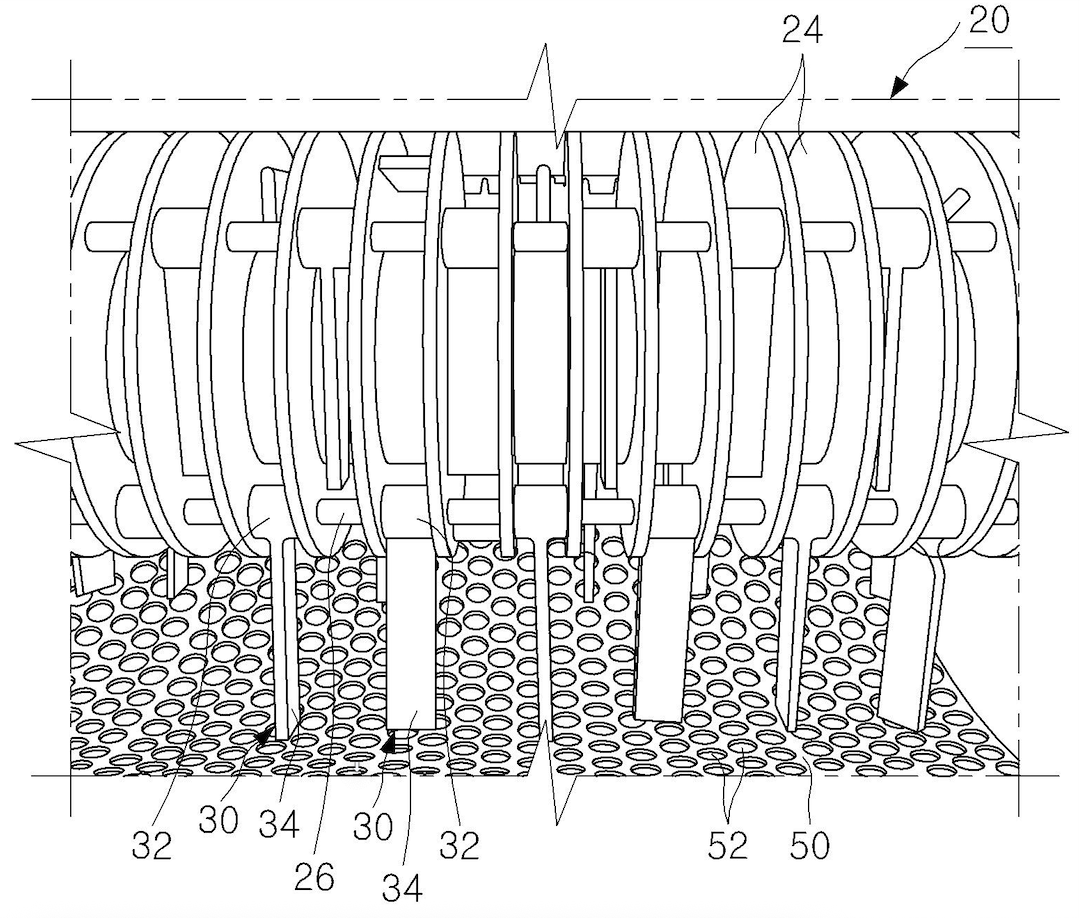

This Impact Composite Sorter is designed with three core components: sorting section, driving section, and screen. The sorting section consists of shafts, discs, connecting axes, and rotating blades, which effectively separate foreign materials and moisture by impacting the input waste with centrifugal force. The driving section provides centrifugal force to each sorting section, and the screen allows only separated foreign materials and moisture to fall downward by their own weight. Optimal sorting efficiency is achieved through the free rotation mechanism of rotating blades and the rounded screen design.

- Perfect separation of foreign materials and moisture from waste through impact using centrifugal force

- Simultaneous moisture drying and appropriate size cutting through wind power generation

- Innovative design of freely rotating blades and rounded screen

- Maximized efficiency for large-capacity waste processing with multiple sorting sections

Technology Effects and Advantages

This Impact Composite Sorter demonstrates superior performance compared to existing sorting methods. Through systematic waste treatment using centrifugal impact and wind drying, the efficiency of foreign material and moisture separation has been improved to near perfection, and

by moving away from conventional landfill or incineration methods, waste can be directly utilized as fuel or recycled raw materials in industrial sites, reducing processing costs and preventing environmental pollution. In particular, by completely removing foreign materials such as soil and moisture from high-calorific waste synthetic resins

to enable maximum calorific value, it is an innovative technology that simultaneously improves fuel efficiency and the quality of recycled raw materials.