CRUSHING APPARATUS FOR WASTES

- Invention Name: Waste Shredding Equipment

- Field: Waste Treatment Technology, Mechanical Engineering

- Core Technology: Crushing Section, Impact Separation Section

- Objective: Efficient Waste Shredding and Sorting

Equipment Overview

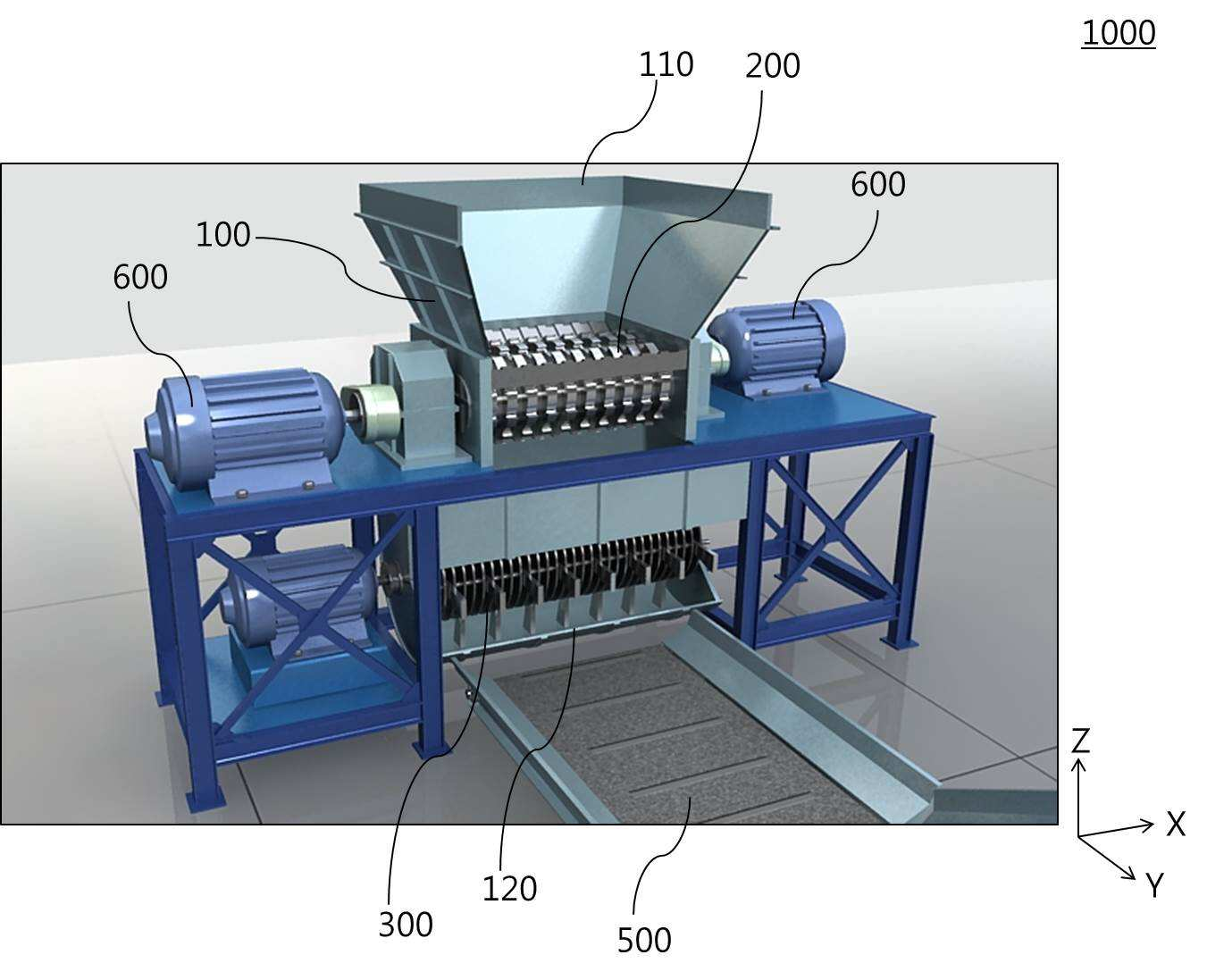

CI Ecotech's Waste Shredding Equipment is an advanced device that effectively breaks open, shreds, and cuts various waste through innovative crushing section and impact separation section technology. Unlike conventional simple roller methods, this equipment utilizes multiple crushing shafts and toothed crushing discs to

systematically separate foreign materials contained in waste and process them to an appropriate size. The first and second rotary crushing sections rotating in different directions cooperate to perform efficient crushing operations, and

effectively separate foreign materials and moisture through the impact separation section, improving the quality of subsequent processing.

The core of this equipment is efficient waste treatment through hook-shaped teeth and a precise rotation mechanism. In particular, the combination of multiple crushing shafts and rotary crushing sections is an innovative solution that overcomes the limitations of existing technologies, simultaneously improving processing efficiency and maintenance convenience.

Core Technology and Equipment Configuration

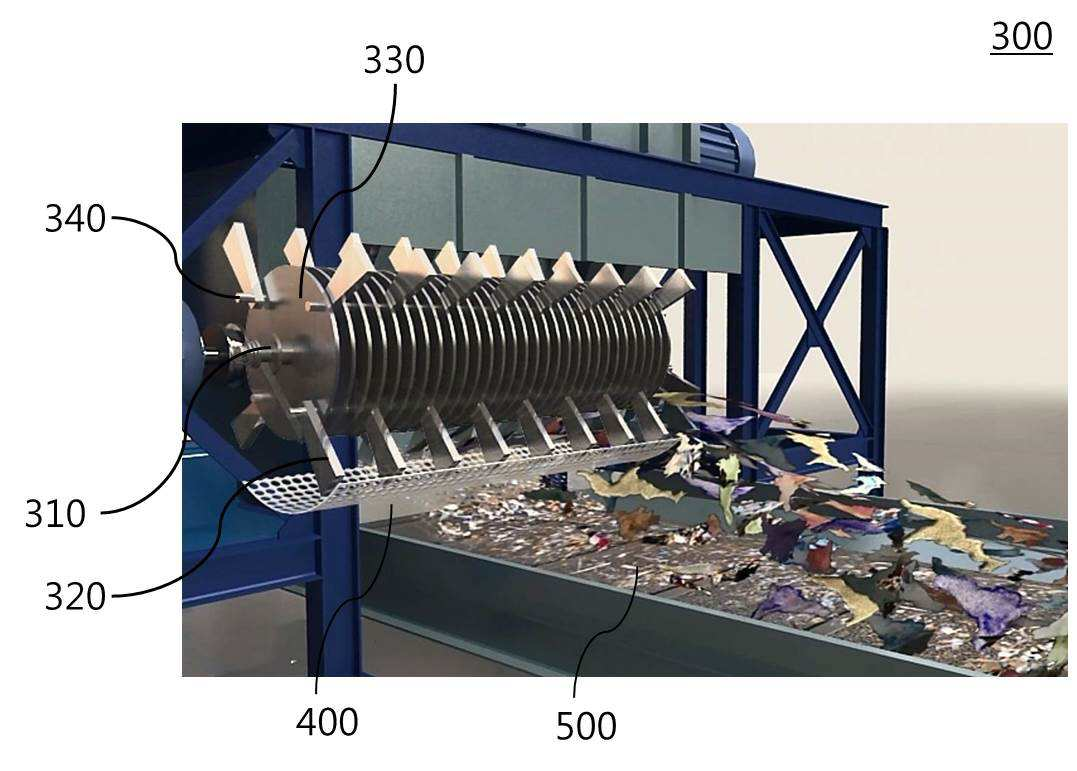

This Waste Shredding Equipment is designed with two core components: crushing section and impact separation section. The crushing section consists of multiple crushing shafts and crushing discs with teeth formed on the outer circumference, effectively breaking open and shredding the input waste. The first and second rotary crushing sections rotating in different directions cooperate to cut the waste to an appropriate size, and the impact separation section effectively separates foreign materials and moisture contained in the waste through rotational force. Each component achieves optimal processing efficiency through precise design.

- Efficient breaking and shredding through multiple crushing shafts and toothed crushing discs

- Cooperative system of first and second rotary crushing sections rotating in different directions

- Maximized waste cutting and shredding efficiency through hook-shaped tooth design

- Effective separation technology for foreign materials and moisture through impact separation section

Technology Effects and Advantages

This Waste Shredding Equipment demonstrates superior performance compared to existing roller methods. Through systematic waste treatment using crushing section and impact separation section, the efficiency of foreign material separation has been greatly improved, and

by moving away from conventional incineration or landfill methods, waste can be efficiently recycled, reducing processing costs and preventing environmental pollution. In particular, by shredding waste to an appropriate size for producing solid fuel products through hook-shaped teeth and a precise rotation mechanism,

it is an innovative technology that prevents equipment failures in downstream processes and improves the quality of final products.