AN APPARATUS FOR COLLECTING FILM

- Invention Name: Film Recovery Equipment

- Field: Waste Treatment, Film Recycling

- Core Technology: Roller System, Blower Device

- Objective: Efficient Vinyl/Film Recovery

Film Recovery Equipment Overview

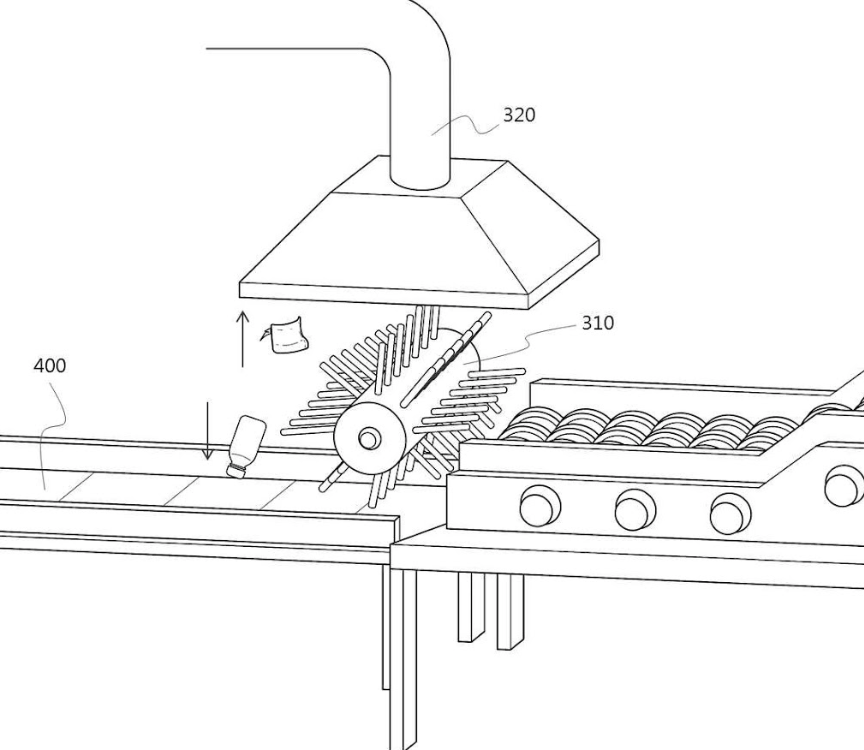

CI Ecotech's Film Recovery Equipment is an innovative film recovery system that enables recycling by efficiently recovering lightweight films such as vinyl and film generated during the waste treatment process through integrated technology of impact sorter, disc sorter, and roller system. Unlike conventional manual work or simple blower methods, this equipment performs primary separation with an impact sorter to

effectively separate film from heavy waste, and then performs secondary sorting and unidirectional transfer through a disc sorter. A rotating roller at a predetermined speed placed at one end of the transfer direction and a blower device at the top cooperate to

efficiently suck in and recover film, and optimize recovery performance through adjustment of blade shape, arrangement, and angle.

The core of this film recovery equipment is primary separation through the impact sorter and efficient film recovery through the linkage of the roller-blower system. In particular, the blade group design of the roller body and the 3-zone structure of the blower fan are innovative solutions that overcome the limitations of existing technologies, simultaneously realizing recovery efficiency and power savings.

Core Technology and Equipment Configuration

This Film Recovery Equipment is an innovative integrated system consisting of an impact sorter, disc sorter, roller system, and blower device. The impact sorter strikes and sorts waste to perform primary separation of film, and the disc sorter is responsible for secondary sorting and unidirectional transfer. The roller placed at one end of the transfer direction consists of a shaft and multiple blades, rotating at a predetermined speed, and the upper blower device consists of a blower, drive unit, and duct, efficiently sucking in and recovering film caught on the roller. Optimal film recovery efficiency is achieved through angle adjustment of blade groups and the 3-zone structure of the blower fan.

- Maximized film recovery efficiency through primary separation with impact sorter

- Continuous secondary sorting and transfer through linkage of disc sorter and roller system

- Optimized film recovery through blade group shape, arrangement, and angle adjustment

- Power savings and improved suction efficiency with 3-zone fan structure of blower device

Technology Effects and Advantages

This Film Recovery Equipment demonstrates superior performance compared to existing manual methods or simple blower methods. Primary separation through the impact sorter effectively separates film from heavy waste, greatly improving recovery efficiency, and

efficient film recovery is possible with less power through the linkage of the roller system and blower device. In particular, through blade shape, arrangement, angle adjustment and the 3-zone structure of the blower fan,

it is an innovative film recovery technology that simultaneously realizes maximized collection efficiency for film recycling, reduced environmental pollution, and power cost savings.